MANUFACTURING OF FINISHED PARTSFaroldi2022-03-30T18:43:44+00:00

Execution of designed items with T.I.G., M.I.G., M.A.G. weldings and A1 category pressurized vessels.

High level of proficiency in the making of stainless steel carpentry.

Manufacturing line service with the support of experienced “partners” for finishing touches, removal of shavings, deformation, painting, zinccoating and electrogalvanic, packaging of finished parts ready for assembly.

We design packaging for every possible need, overseas shipment included.

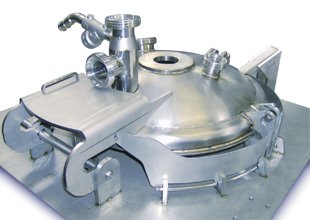

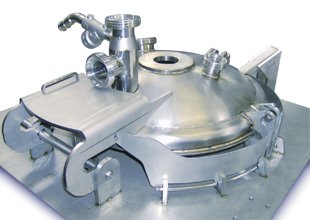

Construction of food processor lid in AISI 304 on assembly jig.

Peened carpentry, entrance doors to the Basilica of Padre Pio in San Giovanni Rotondo (Italy).

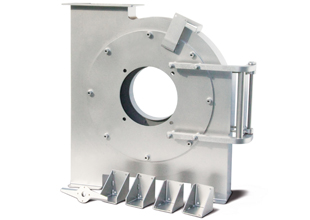

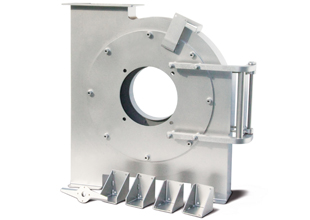

Realization of spiral in AISI 316.

Bostwick’s Consistometer: scientific tool to determine the consistency of fluid foods, built in AISI 316L stainless steel.

Peened carpentry, Basilica of Padre Pio in San Giovanni Rotondo (Italy) front detail.

Interlocking carpentry of water-jet cut and satin finished architectural elements in AISI 304.

For info and quote requests, send an e-mail to: u.commerciale@faroldi.it