CERTIFIED MICRO SHOT INOX-PEENING

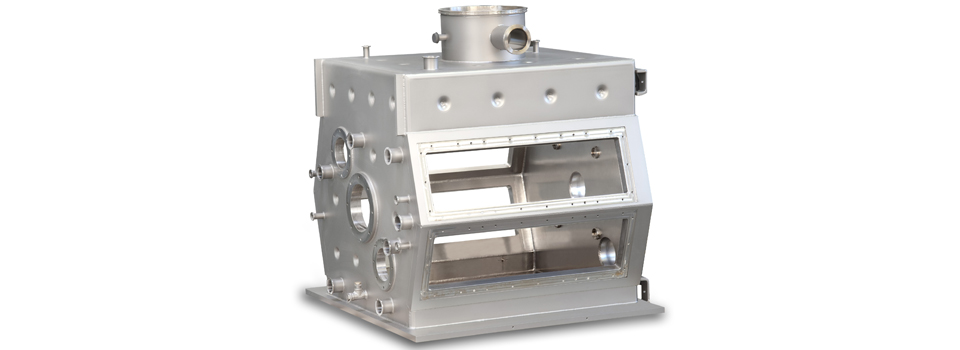

Obtained through certified INOX-PEEN technology, with three outfitted tunnels 9.0×4.8×4.5 m, maximum weight 3.5 t.

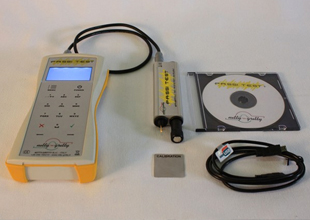

The surface treatment is realized with micro ceramic or vitreous grit, stainless steel and corundum spheres, guaranteed by a roughness check and a certification of the process.

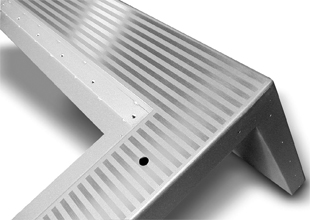

Our finish is characterized by a controlled roughness, which insures the sanitization and easy cleaning of the treated surfaces. This quality has been widely appreciated by major producers of food and pharmaceutical plants, architecture and graphic design firms.

We research, offer and recreate any type of finish and effect.

The treatment is preceded by degreasing, obtained through surfactants, which is followed by a wash with demineralized water to avoid the absorption of any contaminated residue, which in time may ignite critical corrosion processes.

In case the material is highly contaminated, the micro shot peening is preceded by the white corundum treatment. We supervise pickling, certified passivation, electropolishing; we design packaging and manage packing-list for every possible need, overseas shipment included.

CHEMICAL PASSIVATION

The inoxidizability of stainless steel is due to the invisibly thin protective layer of chromium oxide which spontaneously form upon the surface through the oxidizing action of oxygen in the atmosphere. Passivation dissolves any roaming steel particle as well as any other contaminant which because of mechanical or chemical forces is found on the surface. This leaves the metal bare, thus allowing the oxygen in the atmosphere to reform a protective layer of chromium oxide thicker than the original.

This process increases the resistance to corrosion in a truly costeffective way.

For info and quote requests, send an e-mail to: u.commerciale@faroldi.it